- Sign In

- |

- Sign Up

- |

- My Quote (0)

- |

- CART (0)

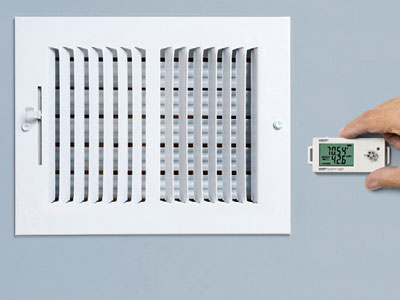

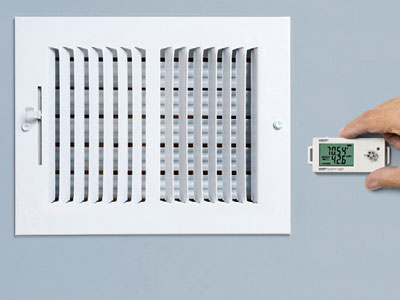

Split-core AC current transformer for use with HOBO U12 and UX120-06M data loggers and HOBO ZW data nodes external input channels.

Split-core AC current transformer for use with HOBO U12 and UX120-06M data loggers and HOBO ZW data nodes external input channels.

A split-core AC current sensor responsive over the range of 10 to 100 amps AC for use with U12, UX120, and ZW data loggers with external input channels. With an input current of AC current, sine wave, single phase 50 Hz or 60 Hz, load power factor 0.5 to 1.0 lead or lag.

Features

With so many choices of data loggers available today, it can be challenging to know which one is right for your application. There is a range of different types of data logging devices available, including:

Stand-alone

Stand-alone data loggers are compact and easy to set up and deploy. You have a choice of low-cost, stand-alone loggers with internal sensors for measurements at the logger location, or multi-channel loggers with external sensors for monitoring at some distance from the logger. All stand-alone loggers communicate with a PC or Mac via USB.

Web-based

Web-based systems enable real-time, remote access to your data via cellular, Wi-Fi, or Ethernet communications. They can be configured with any combination of external smart sensors, and have been designed with an industrial-grade, tamper-proof enclosure. This enables them to be used in indoor HVAC/R monitoring projects, as well as outdoor projects such as rooftop HVAC/R system monitoring.

Wireless sensor

Wireless data nodes are ideal for centralized, on-site monitoring of building performance. By combining data logger and transmitter in one, data nodes transmit high-accuracy, real-time data from dozens of points to a central PC or Mac. This eliminates the need to manually retrieve and offload individual data loggers, saving time and money. Should an obstruction block the wireless flow of data, these MESH networking devices automatically reroute the path to the receiver – all without manual intervention.

Once you know what parameters you'll be measuring, you need to make sure to choose a data logger that provides the accuracy you need. Accuracy specifications vary widely among different data loggers, so when shopping around be sure to look for accuracy charts that indicate accuracy over an entire measurement range – not just a single value. As a general rule, it's good to look for a data logger that will provide at least twice the accuracy of what your application requires.

Another important factor is data logger resolution, which refers to the number of increments of a value a data logger is capable of reporting. This is important if you plan to deploy a logger for months at a time, or want the logger to record data in 10-second intervals. You should also ask about a logger's response time.

If you're unsure about your application's accuracy and resolution requirements, an experienced supplier should be able to help you determine which product will meet your needs.

All data loggers use software for setup and configuration, but some loggers require more customization than others. User-friendly loggers can be set up and launched by someone with no training in electrical wiring or programming.

Depending on the type of data logger, the user can connect to a PC or mobile device via a USB connection, cellular, Wi-Fi, Ethernet or Bluetooth Low Energy (BLE) technology. The accompanying logger software automatically recognizes the device and asks a series of configuration questions. The user simply chooses a sampling interval and selects an immediate or designated future launch time. There is no wiring or programming involved, even for multi-component weather stations.

Ask about the software that comes with the data logger. Applications are generally Windows and MAC-based, and highly intuitive so the learning curve is minimal. The software should enable you to quickly and easily perform tasks such as setting configuration parameters, designating launch times, and offloading data with point-and-click simplicity. For BLE-enabled monitoring, configuring the loggers and managing data simply requires downloading a free app to your mobile device.

Check the software's graphing and analysis capabilities, including whether you can combine graphs to compare data between sites, or if you can view all of a site's data clearly in a single graph. Depending on the scope and type of data, the manufacturer may also have special application-specific software available.

There are a number of other capabilities to look for. For example, the software should allow you to select a range of data in a graph, and display the maximum, minimum, average, and standard deviation for the measurements in that range. It should also allow you to save data analysis projects for future use.

Finally, since data often need to be passed into other software programs such as spreadsheets or modeling programs, make sure that the logger software allows you to quickly and easily export data. Also be sure that you can print graphs and tables, which is especially important for documentation purposes.

Data loggers are generally extremely low-power devices. However, because they are used in a variety of environmental conditions and sample at different rates, battery life can vary widely. As a general rule of thumb, make sure the data logger you select has a battery life of at least one year.

Most logger manufacturers' software will indicate when the logger's battery power is getting low. You may also want to ask your supplier about whether or not the data logger battery is user-replaceable, as this can eliminate the time and expense of having to ship the logger back to the manufacturer for battery replacement.

The storage capacity of a data logger can vary widely between models. In general, be sure to buy a logger that provides enough on-board memory to cover the sampling rate and deployment duration you need. If you are unsure of how often you will be able to offload and relaunch your deployed data loggers, it may be best to buy a logger with more memory to prevent any gaps in data.

| Range | 10-100 Amps |

| Accuracy with H8 | ±5.0% of full scale |

| Accuracy with U12 | ±4.5% of full scale |

| Accuracy with UX120-006M | ±2.1% of full scale |

| Response time (from 10% to 90% of amplitude) | 100 milliseconds |

| Input current | AC current, sine wave, single phase 50 Hz or 60 Hz, load power factor 0.5 to 1.0 lead or lag |

| Voltage rating | 600 VAC |

| Construction and operating environment | Molded plastic housing for indoor use per UL508; pivoting leg (leg on CTV-D and CTV-E units is fully removable); UL listed. |

| Cable length | 1.8m cable (6 foot) |

With so many choices of data loggers available today, it can be challenging to know which one is right for your application. There is a range of different types of data logging devices available, including:

Stand-alone

Stand-alone data loggers are compact and easy to set up and deploy. You have a choice of low-cost, stand-alone loggers with internal sensors for measurements at the logger location, or multi-channel loggers with external sensors for monitoring at some distance from the logger. All stand-alone loggers communicate with a PC or Mac via USB.

Web-based

Web-based systems enable real-time, remote access to your data via cellular, Wi-Fi, or Ethernet communications. They can be configured with any combination of external smart sensors, and have been designed with an industrial-grade, tamper-proof enclosure. This enables them to be used in indoor HVAC/R monitoring projects, as well as outdoor projects such as rooftop HVAC/R system monitoring.

Wireless sensor

Wireless data nodes are ideal for centralized, on-site monitoring of building performance. By combining data logger and transmitter in one, data nodes transmit high-accuracy, real-time data from dozens of points to a central PC or Mac. This eliminates the need to manually retrieve and offload individual data loggers, saving time and money. Should an obstruction block the wireless flow of data, these MESH networking devices automatically reroute the path to the receiver – all without manual intervention.

Once you know what parameters you'll be measuring, you need to make sure to choose a data logger that provides the accuracy you need. Accuracy specifications vary widely among different data loggers, so when shopping around be sure to look for accuracy charts that indicate accuracy over an entire measurement range – not just a single value. As a general rule, it's good to look for a data logger that will provide at least twice the accuracy of what your application requires.

Another important factor is data logger resolution, which refers to the number of increments of a value a data logger is capable of reporting. This is important if you plan to deploy a logger for months at a time, or want the logger to record data in 10-second intervals. You should also ask about a logger's response time.

If you're unsure about your application's accuracy and resolution requirements, an experienced supplier should be able to help you determine which product will meet your needs.

All data loggers use software for setup and configuration, but some loggers require more customization than others. User-friendly loggers can be set up and launched by someone with no training in electrical wiring or programming.

Depending on the type of data logger, the user can connect to a PC or mobile device via a USB connection, cellular, Wi-Fi, Ethernet or Bluetooth Low Energy (BLE) technology. The accompanying logger software automatically recognizes the device and asks a series of configuration questions. The user simply chooses a sampling interval and selects an immediate or designated future launch time. There is no wiring or programming involved, even for multi-component weather stations.

Ask about the software that comes with the data logger. Applications are generally Windows and MAC-based, and highly intuitive so the learning curve is minimal. The software should enable you to quickly and easily perform tasks such as setting configuration parameters, designating launch times, and offloading data with point-and-click simplicity. For BLE-enabled monitoring, configuring the loggers and managing data simply requires downloading a free app to your mobile device.

Check the software's graphing and analysis capabilities, including whether you can combine graphs to compare data between sites, or if you can view all of a site's data clearly in a single graph. Depending on the scope and type of data, the manufacturer may also have special application-specific software available.

There are a number of other capabilities to look for. For example, the software should allow you to select a range of data in a graph, and display the maximum, minimum, average, and standard deviation for the measurements in that range. It should also allow you to save data analysis projects for future use.

Finally, since data often need to be passed into other software programs such as spreadsheets or modeling programs, make sure that the logger software allows you to quickly and easily export data. Also be sure that you can print graphs and tables, which is especially important for documentation purposes.

Data loggers are generally extremely low-power devices. However, because they are used in a variety of environmental conditions and sample at different rates, battery life can vary widely. As a general rule of thumb, make sure the data logger you select has a battery life of at least one year.

Most logger manufacturers' software will indicate when the logger's battery power is getting low. You may also want to ask your supplier about whether or not the data logger battery is user-replaceable, as this can eliminate the time and expense of having to ship the logger back to the manufacturer for battery replacement.

The storage capacity of a data logger can vary widely between models. In general, be sure to buy a logger that provides enough on-board memory to cover the sampling rate and deployment duration you need. If you are unsure of how often you will be able to offload and relaunch your deployed data loggers, it may be best to buy a logger with more memory to prevent any gaps in data.

| Range | 10-100 Amps |

| Accuracy with H8 | ±5.0% of full scale |

| Accuracy with U12 | ±4.5% of full scale |

| Accuracy with UX120-006M | ±2.1% of full scale |

| Response time (from 10% to 90% of amplitude) | 100 milliseconds |

| Input current | AC current, sine wave, single phase 50 Hz or 60 Hz, load power factor 0.5 to 1.0 lead or lag |

| Voltage rating | 600 VAC |

| Construction and operating environment | Molded plastic housing for indoor use per UL508; pivoting leg (leg on CTV-D and CTV-E units is fully removable); UL listed. |

| Cable length | 1.8m cable (6 foot) |